| |

|

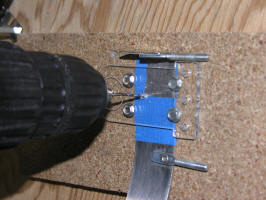

Take

the template and screw it to a flat piece of scrap with four of the #6

sheetmetal screws from the machine. You want to keep to the right, as

you see here. Take

the template and screw it to a flat piece of scrap with four of the #6

sheetmetal screws from the machine. You want to keep to the right, as

you see here. |

Remove

the template and screws from the wood, and drive the top two screws

fully through the template. Remove

the template and screws from the wood, and drive the top two screws

fully through the template. |

Screw

the template back into the wood with just the top screw, most of the way

down. Insert a guide so that the edge of the tape aligns with the pilot

hole. Put the bottom screws in, and tighten it down. Make sure that

everything is aligned. Remember, you want a hole near the top and

aligned with the magnet. Screw

the template back into the wood with just the top screw, most of the way

down. Insert a guide so that the edge of the tape aligns with the pilot

hole. Put the bottom screws in, and tighten it down. Make sure that

everything is aligned. Remember, you want a hole near the top and

aligned with the magnet. |

Use

a small drill to make a pilot hole. I used 1/8" and a drop of WD-40. You

will be fighting a bit with the other end of the ball guide. Use

a small drill to make a pilot hole. I used 1/8" and a drop of WD-40. You

will be fighting a bit with the other end of the ball guide. |

Once

you have a dimple, you can take the guide out of the template. Once

you have a dimple, you can take the guide out of the template. |

I

drilled the first one all the way through. It turns out that a dimple is

enough. I

drilled the first one all the way through. It turns out that a dimple is

enough. |

Next,

I used a 17/64 drill to make my opto hole. I went a little bigger than

1/4" for test purposes. Again, a little WD-40 helps. Clean the rough

edges of the hole by hand with a bigger drill when you are done. Next,

I used a 17/64 drill to make my opto hole. I went a little bigger than

1/4" for test purposes. Again, a little WD-40 helps. Clean the rough

edges of the hole by hand with a bigger drill when you are done. |

Repeat

for the other guide. Here's why you have to be towards the right.

There's a bracket that interferes with the scrap wood. Repeat

for the other guide. Here's why you have to be towards the right.

There's a bracket that interferes with the scrap wood. |

Here's

the first one installed in the machine. Here's

the first one installed in the machine. |

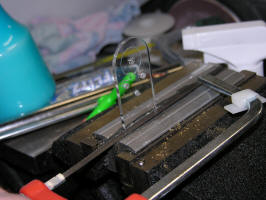

And

the second, with a 1/4" Lucite bar through the holes. As you can see,

the template makes this very easy. And

the second, with a 1/4" Lucite bar through the holes. As you can see,

the template makes this very easy. |

Remove

the opto brackets from the boards by unscrewing the #4 screws. Remove

the opto brackets from the boards by unscrewing the #4 screws. |

Insert

a drill through both holes - 3/16" is good - and put the opto on it for

alignment. You want to be 1/* or ao away from the guide. Drill a

pilot, and insert the first screw. Insert

a drill through both holes - 3/16" is good - and put the opto on it for

alignment. You want to be 1/* or ao away from the guide. Drill a

pilot, and insert the first screw. |

Check

alignment, drill the other pilot hole, and insert the second screw. No

need to go tight yet. Check

alignment, drill the other pilot hole, and insert the second screw. No

need to go tight yet.

Remove the screws and plastic when done. |

Repeat

for the other side. The ball guides are not parallel, the drill is your

guide! Repeat

for the other side. The ball guides are not parallel, the drill is your

guide! |

Reassemble

the opto boards to the plastic. The dimples are on the board side. They

accommodate the connector wires. Tighten the screws to snug, don't

overdo it. You could put a drop of CA adhesive in the threads first,

these won't need to be disassembled again. Reassemble

the opto boards to the plastic. The dimples are on the board side. They

accommodate the connector wires. Tighten the screws to snug, don't

overdo it. You could put a drop of CA adhesive in the threads first,

these won't need to be disassembled again. |

Put

the optos in the machine. Don't tighten them down to much. Acrylic is

strong but brute force will crack it. Put

the optos in the machine. Don't tighten them down to much. Acrylic is

strong but brute force will crack it.Dress the wires as you like. The

receiver wires run as shown. |

And

here are the transmitter opto and wires. And

here are the transmitter opto and wires.

That's it for wiring, connect them up under the playfield and

re-assemble the machine. |

Last

step. We're almost done with the template. Put it in a vise, score it

with a saw and then whack it with your hand. It will break into to

parts. the top part is scrap, we want the piece left in the vise, which

is part of the magnet spacer. Last

step. We're almost done with the template. Put it in a vise, score it

with a saw and then whack it with your hand. It will break into to

parts. the top part is scrap, we want the piece left in the vise, which

is part of the magnet spacer. |